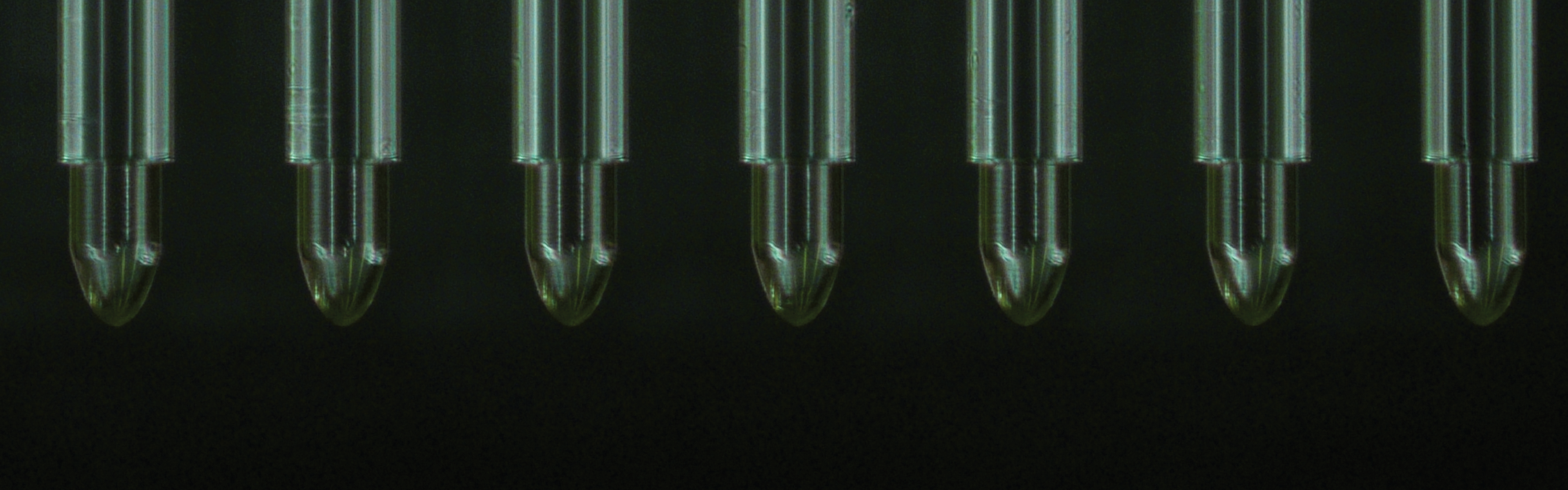

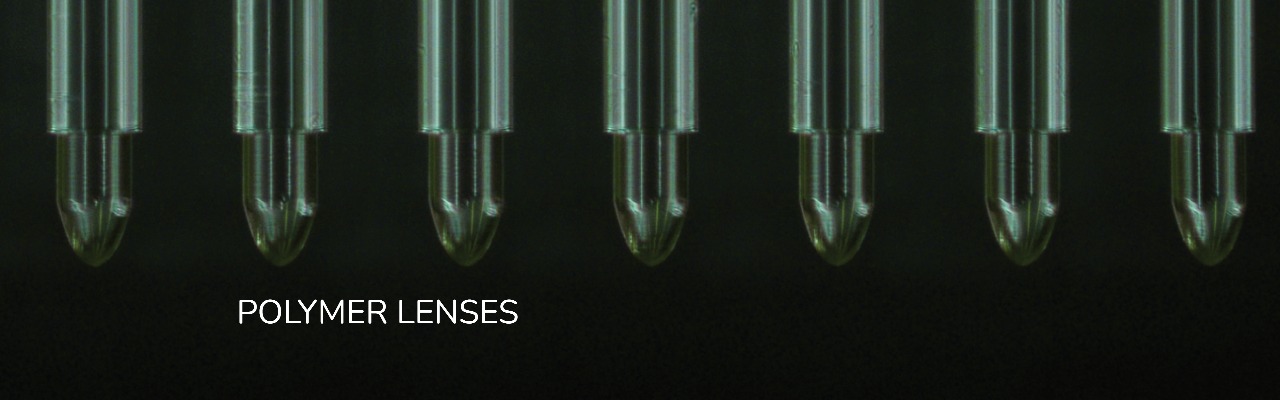

Facet Attached Microlenses

Two photon lithography enables writing custom 3D polymer structures on a variety of substrates and orientations. This may include lenses and total internal reflection mirrors that can be used to collimate, collect, and redirect light. Some examples of applications for these structures include:

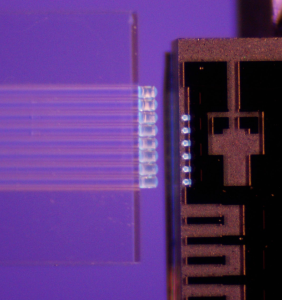

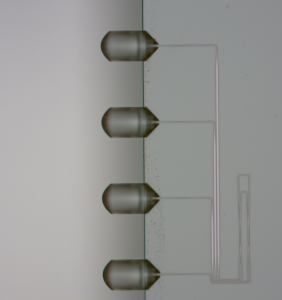

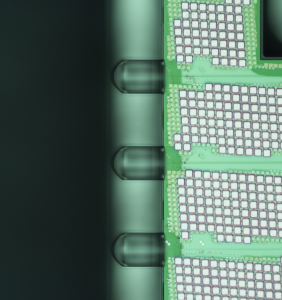

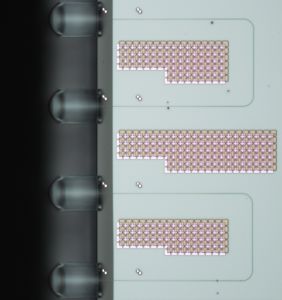

- Lenses on waveguide edge couplers or vertical emission ports

- Lenses and mirrors on lasers, fibers, etc.

- Any other self-connected object – use your imagination!

Facet Attached Microlens Evaluation Kit & Lens Subscription

Dream Photonics is offering a full rapid and low-loss testing solution for your photonic integrated circuits. By 3D printing polymer microlenses on the PIC and on a fiber array, the alignment requirements for edge coupling are significantly relaxed. This enables the use of low-cost translation stages to perform edge coupling to your PIC and with low insertion loss.

Dream Photonics will supply writing of up to 10 chips with 16 lenses per chip (total of 160 lenses) per year on customer supplied chips with compatible edge coupler interfaces. Dream Photonics will perform annual maintenance of the suitcase which will include replacement of any defective parts, replacement of the supplied fiber arrays if needed, and qualification of the test station.

The evaluation kit and subscription service is $25,000 USD/yr, and the full spec sheet is available via the link below.

Applied Nanotools

- Low insertion loss (<2 dB)

- Broadband operation (> 100 nm)

- Polarization maintaining (0.5 dB polarization-dependent loss)

- High power handling (> 700 mW at telecom wavelengths)

- Can be used for as a solution for testing and/or packaging

- Reflow compatible if pursuing packaging

- Telcordia Ref. 3.3.2.2: 225 cycles of -40 °C to +85 °C (> 200 h)

- Telcordia Ref. 3.3.2.3: 85°C / 85% humidity, 3500 h

Tower Semiconductor

- Low insertion loss (<2 dB)

- Broadband operation (> 100 nm)

- Polarization maintaining (0.5 dB polarization-dependent loss)

- High power handling (> 700 mW at telecom wavelengths)

- Can be used for as a solution for testing and/or packaging

- Reflow compatible if pursuing packaging

- Telcordia Ref. 3.3.2.2: 225 cycles of -40 °C to +85 °C (> 200 h)

- Telcordia Ref. 3.3.2.3: 85°C / 85% humidity, 3500 h

Advanced Microfoundry

- Low insertion loss (<2 dB)

- Broadband operation (> 100 nm)

- Polarization maintaining (0.5 dB polarization-dependent loss)

- High power handling (> 700 mW at telecom wavelengths)

- Can be used for as a solution for testing and/or packaging

- Reflow compatible if pursuing packaging

- Telcordia Ref. 3.3.2.2: 225 cycles of -40 °C to +85 °C (> 200 h)

- Telcordia Ref. 3.3.2.3: 85°C / 85% humidity, 3500 h